What products are die-cutting machines mainly used as essential equipment in the production of

[2025-07-10]View More >

What factors affect the die-cutting accuracy of fully automatic die-cutting?

[2025-07-01]View More >

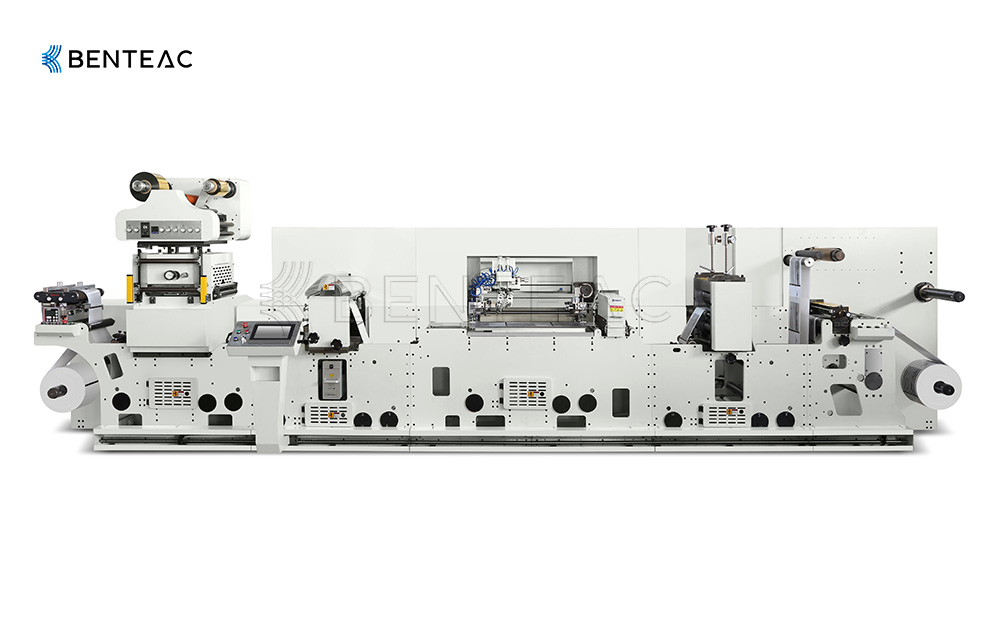

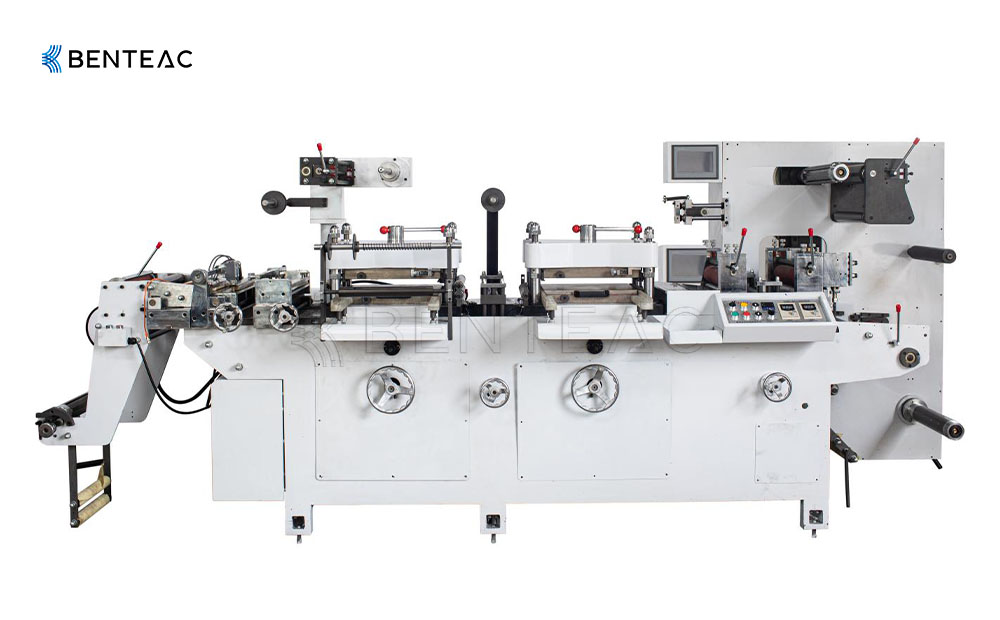

What types of fully automatic high-speed die-cutting machines can be classified into?

[2025-06-30]View More >

How to solve the problem of low precision of fully automatic die-cutting machines?

[2025-06-28]View More >

How to solve the problem of low precision of fully automatic die-cutting machines?

[2025-06-28]View More >

What are the advantages of fully automatic die-cutting machines?

[2025-06-27]View More >

What are the steps to adjust the die-cutting pressure of a fully automatic die-cutting machine

[2025-06-26]View More >

The usage habits of die-cutting machines

[2025-06-25]View More >

What are the requirements for the debugging of die-cutting machines?

[2025-06-20]View More >